TRANSFORMER CORE EARTHING BASIC INFORMATION

What Is Transformer Core Earthing?

Core earthing

Before concluding the description of core construction, mention should be made of the subject of core earthing. Any conducting metal parts of a transformer, unless solidly bonded to earth, will acquire a potential in operation which depends on their location relative to the electric field within which they lie.

In theory, the designer could insulate them from earthed metal but, in practice, it is easier and more convenient to bond them to earth. However, in adopting this alternative, there are two important requirements:

ž The bonding must ensure good electrical contact and remain secure throughout the transformer life.

ž No conducting loops must be formed, otherwise circulating currents will result, creating increased losses and/or localised overheating.

Metalwork which becomes inadequately bonded, possibly due to shrinkage or vibration, creates arcing which will cause breakdown of insulation and oil and will produce gases which may lead to Buchholz relay operation, where fitted, or cause confusion of routine gas-in-oil monitoring results y masking other more serious internal faults, and can thus be very troublesome in service.

The core and its framework represent the largest bulk of metalwork requiring to be bonded to earth. On large, important transformers, connections to core and frames can be individually brought outside the tank via 3.3 kV bushings and then connected to earth externally.

This enables the earth connection to be readily accessed at the time of initial installation on site and during subsequent maintenance without lowering the oil level for removal of inspection covers so that core insulation resistance checks can be carried out.

In order to comply with the above requirement to avoid circulating currents, the core and frames will need to be effectively insulated from the tank and from each other, nevertheless it is necessary for the core to be very positively located within the tank particularly so as to avoid movement and possible damage during transport.

It is usual to incorporate location brackets within the base of the tank in order to meet this requirement. Because of the large weight of the core and windings these locating devices and the insulation between them and the core and frames will need to be physically very substantial, although the relevant test voltage may be modest.

POWER TRANSFORMER | DISTRIBUTION TRANSFORMER | TRANSFORMER DESIGN | TRANSFORMER PRINCIPLES | TRANSFORMER THEORY | TRANSFORMER INSTALLATION | TRANSFORMER TUTORIALS

THREE PHASE PAD MOUNTED TRANSFORMERS BASIC AND TUTORIALS

THREE PHASE PAD MOUNTED TRANSFORMERS BASIC INFORMATION

Example Of Three Phase Pad Mounted Transformers

Three-Phase Pad-Mounted Transformers

Three-phase pad-mounted transformers are typically applied to serve commercial and industrial threephase loads from underground distribution systems. Traditionally, there have been two national standards that detailed requirements for pad-mounted transformers — one for live front (ANSI C57.12.22) and one for dead front (IEEE C57.12.26). The two standards have now been combined into one for all pad mounts, designated IEEE C57.12.34.

Live Front

Live-front transformers are specified as radial units and thus do not come with any fuse protection. See Figure 2.2.29.

The primary compartment is on the left, and the secondary compartment is on the right, with a rigid barrier separating them. The secondary door must be opened before the primary door can be opened.

Stress-cone-terminated primary cables rise vertically and connect to the terminals on the end of the high-voltage bushings. Secondary cables rise vertically and are terminated on spades connected to the secondary bushings.

Units with a secondary of 208Y/120 V are available up to 1000 kVA. Units with a secondary of 480Y/277 V are available up to 2500 kVA. Although not detailed in a national standard, there are many similar types available.

A loop-style live front (Figure 2.2.30) can be constructed by adding fuses mounted below the primary bushings. Two primary cables are then both connected to the bottom of the fuse. The loop is then made at the terminal of the high-voltage bushing, external to the transformer but within its primary compartment.

Dead Front

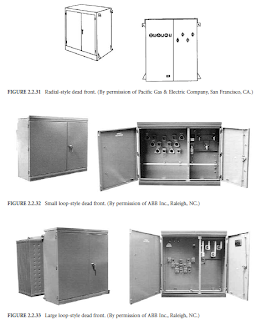

Both radial- and loop-feed dead-front pad-mounted transformers are detailed in the standard. Radialstyle units have three primary bushings arranged horizontally, as seen in Figure 2.2.31. Loop-style units have six primary bushings arranged in a V pattern, as seen in Figure 2.2.32 and Figure 2.2.33.

In both, the primary compartment is on the left, and the secondary compartment is on the right, with a rigid barrier between them. The secondary door must be opened before the primary door can be opened.

The primary cables are terminated with separable insulated high-voltage connectors, commonly referred to as 200-A elbows, specified in IEEE Standard 386. These plug onto the primary bushings, which can be either bushing wells with an insert, or they can be integral bushings.

Bushing wells with inserts are preferred, as they allow both the insert and elbow to be easily replaced. Units with a secondary of 208Y/ 120 V are available up to 1000 kVA. Units with a secondary of 480Y/277 V are available up to 2500 kVA.

Example Of Three Phase Pad Mounted Transformers

Three-Phase Pad-Mounted Transformers

Three-phase pad-mounted transformers are typically applied to serve commercial and industrial threephase loads from underground distribution systems. Traditionally, there have been two national standards that detailed requirements for pad-mounted transformers — one for live front (ANSI C57.12.22) and one for dead front (IEEE C57.12.26). The two standards have now been combined into one for all pad mounts, designated IEEE C57.12.34.

Live Front

Live-front transformers are specified as radial units and thus do not come with any fuse protection. See Figure 2.2.29.

The primary compartment is on the left, and the secondary compartment is on the right, with a rigid barrier separating them. The secondary door must be opened before the primary door can be opened.

Stress-cone-terminated primary cables rise vertically and connect to the terminals on the end of the high-voltage bushings. Secondary cables rise vertically and are terminated on spades connected to the secondary bushings.

Units with a secondary of 208Y/120 V are available up to 1000 kVA. Units with a secondary of 480Y/277 V are available up to 2500 kVA. Although not detailed in a national standard, there are many similar types available.

A loop-style live front (Figure 2.2.30) can be constructed by adding fuses mounted below the primary bushings. Two primary cables are then both connected to the bottom of the fuse. The loop is then made at the terminal of the high-voltage bushing, external to the transformer but within its primary compartment.

Dead Front

Both radial- and loop-feed dead-front pad-mounted transformers are detailed in the standard. Radialstyle units have three primary bushings arranged horizontally, as seen in Figure 2.2.31. Loop-style units have six primary bushings arranged in a V pattern, as seen in Figure 2.2.32 and Figure 2.2.33.

In both, the primary compartment is on the left, and the secondary compartment is on the right, with a rigid barrier between them. The secondary door must be opened before the primary door can be opened.

The primary cables are terminated with separable insulated high-voltage connectors, commonly referred to as 200-A elbows, specified in IEEE Standard 386. These plug onto the primary bushings, which can be either bushing wells with an insert, or they can be integral bushings.

Bushing wells with inserts are preferred, as they allow both the insert and elbow to be easily replaced. Units with a secondary of 208Y/ 120 V are available up to 1000 kVA. Units with a secondary of 480Y/277 V are available up to 2500 kVA.

Subscribe to:

Comments (Atom)

Previous Articles

-

▼

2025

(123)

-

▼

October

(123)

- Understanding Tensile and Compressive Forces in Wi...

- Understanding Axial Forces in Power Transformer De...

- Understanding the Dynamics of Winding Forces in El...

- Understanding Short-Circuit Forces in Power Transf...

- Understanding the Forces on Conductors in Power Tr...

- Ensuring Transformer Efficiency: Cooling Technique...

- Understanding Oil Flow and Temperature Distributio...

- Understanding Eddy Current Loss and Cooling in Pow...

- Understanding Winding Hot Spot Rise in Transformers

- Understanding Temperature Dynamics in Power Transf...

- Understanding Transformer Cooling: The Role of Dir...

- Understanding Radiator Placement and Cooling Metho...

- Understanding Transformer Cooling: The Role of Oil...

- Understanding Transformer Winding Hot Spot Factors...

- Enhancing Transformer Longevity with Natural Ester...

- Understanding Inrush Current in Transformer Operation

- Understanding Transformer Core Characteristics and...

- Understanding the Impact of Third Harmonic Voltage...

- Understanding No-Load Losses in Cold-Rolled Lamina...

- Understanding No-Load Loss in Transformer Core Design

- Understanding Transformer Design: Key Factors in E...

- Exploring the Dynamics of Steel in Transformer Cores

- Understanding Power Transformer Design: Key Concep...

- Understanding Transformer Design: Balancing Effici...

- Understanding Transformer Connections: A Primer on...

- Understanding the Winding Space Factor in Transfor...

- Understanding Load Loss and Transformer Design: A ...

- Understanding Tap Changers: Enhancing Transformer ...

- Understanding Transformer Efficiency and Voltage R...

- Understanding Transformer Impedance: Key Concepts ...

- Understanding Transformer Losses: No-Load and Load...

- Understanding Power Transformers: Insights into Th...

- Understanding Power Transformers: The Backbone of ...

- Understanding Load Losses and Impedance in Power T...

- Exploring the Intricacies of Magnetism and Sound i...

- Understanding Oil Thermal Behavior and Short-Circu...

- Understanding Insulation and Impedance in Electric...

- Understanding Transformer Insulation: Key Concepts...

- Understanding Transformer Winding Connections and ...

- Understanding Power Transformer Design Practices: ...

- Understanding the Load Loss Test in Power Transfor...

- Understanding Eddy Current Losses in Metals: A Com...

- Understanding Power Loss in Structural Components:...

- Understanding Eddy Loss in Structural Plates: A De...

- Understanding Eddy Currents and Stray Losses in Ma...

- Understanding Stray Losses in Transformers: The Ro...

- Understanding Stray Losses in Transformer Design

- Understanding Eddy Currents and Stray Losses in Po...

- Understanding Flux Density and Over-Excitation in ...

- Understanding Transformer Excitation and Losses: A...

- Understanding Core Loss in Transformers: The Role ...

- Understanding Core Losses in Magnetic Circuits: Hy...

- Understanding Core Losses in Electrical Transformers

- Understanding Zero-Sequence Impedance and Core Con...

- Understanding Single-Phase and Three-Phase Transfo...

- Understanding Transformer Core Designs: A Deep Div...

- Understanding Transformer Vector Groups: A Key to ...

- Understanding Parallel Operation of Transformers: ...

- Understanding Transformer Ratings: Why Volt-Ampere...

- Understanding Transformer Circuit Parameters and E...

- Understanding Transformer Efficiency and Regulation

- Understanding Transformer Short-Circuit Testing an...

- Understanding Transformer Parameters: The Per-Unit...

- Understanding Transformer Representation in Power ...

- Understanding Core Magnetization and Losses in Tra...

- Understanding Practical Transformers: The Mechanic...

- Understanding Ideal Transformer Behavior: A Deep D...

- Understanding Transformers: The Key to Electromagn...

- Understanding Transformers and Reactors: The Backb...

- Understanding Distribution Transformers: Types and...

- Understanding Transformer Fundamentals: Types and ...

- Understanding Transformer Technology: Insights and...

- Understanding SF6 Transformers: Benefits and Chall...

- Understanding Transformer Technology: Materials, D...

- Exploring Specialized Transformers: Beyond the Basics

- Understanding Transformer Design: Key Concepts and...

- Unlocking the Secrets of Transformer Engineering

- Unraveling Transformer Technology: A New Era of In...

- Unlocking Transformer Engineering: Insights from K...

- Exploring the Latest Advancements in Transformer T...

- Unraveling Transformer Engineering: Insights from ...

- Understanding Transformer Engineering: Key Insight...

- Understanding Single-Phase and Three-Phase Transfo...

- Understanding Pad-Mounted Distribution Transformer...

- Understanding Submersible Transformers: Key Featur...

- Understanding Submersible Transformers: Types and ...

- Understanding Transformers: The Backbone of Electr...

- Understanding Vault Installations: The Backbone of...

- Understanding Underground Transformers: A Key Comp...

- Understanding Transformer Polarity and Standards: ...

- Understanding Operational Concerns in Transformer ...

- Understanding Transformer Connections: A Guide to ...

- Understanding Single-Phase and Three-Phase Transfo...

- Understanding Transformer Configurations: A Guide ...

- Advancements in Transformer Design: From Adhesives...

- Understanding Transformer Coolants and Materials: ...

- Understanding the Evolution of Distribution Transf...

- The Evolution of Transformer Core Technology: A Lo...

- The Evolution of Distribution Transformers: From I...

- Innovations in Transformer Design: Paving the Way ...

-

▼

October

(123)