POWER TRANSFORMER | DISTRIBUTION TRANSFORMER | TRANSFORMER DESIGN | TRANSFORMER PRINCIPLES | TRANSFORMER THEORY | TRANSFORMER INSTALLATION | TRANSFORMER TUTORIALS

Showing posts with label Pad Mounted. Show all posts

Showing posts with label Pad Mounted. Show all posts

SINGLE PHASE PAD MOUNTED TRANSFORMER PARTS BASIC INFORMATION AND TUTORIALS

Parts Of Pad-Mounted Single-Phase Distribution Transformers

Single-phase pad mounted distribution transformers are used in underground distribution systems where it is preferable to have underground rather than overhead distribution. An example of a single-phase, pad mounted distribution transformer with its cover raised is shown in below.

Single-phase, pad-mounted transformers are manufactured with ratings from 10 to 167 kVA. All of these distribution transformers are oil-insulated, self-cooled, and made with loop or radial feed. They can meet or exceed ANSI and NEMA standards.

Pad-mounted distribution transformers are enclosed in steel tamper-resistant protective cases designed with low profiles. They are usually painted green to blend in

Submersible single-phase distribution transformers

Single-phase submersible underground transformers are enclosed in round vertical stainless steel tanks that are hermetically sealed for protection against repeated flooding and/or immersion. The terminals, ground pads, and nameplates are mounted on the covers for easy access from ground level.

These transformers are made in ratings of 25 to 167 kVA. Where submersible transformers are to be installed in a trench that is not subject to repeated flooding or immersion, they are enclosed in stainless steel tanks. Their terminals, ground pads, and nameplates are mounted on their covers.

THREE PHASE PAD MOUNTED TRANSFORMERS BASIC AND TUTORIALS

THREE PHASE PAD MOUNTED TRANSFORMERS BASIC INFORMATION

Example Of Three Phase Pad Mounted Transformers

Three-Phase Pad-Mounted Transformers

Three-phase pad-mounted transformers are typically applied to serve commercial and industrial threephase loads from underground distribution systems. Traditionally, there have been two national standards that detailed requirements for pad-mounted transformers — one for live front (ANSI C57.12.22) and one for dead front (IEEE C57.12.26). The two standards have now been combined into one for all pad mounts, designated IEEE C57.12.34.

Live Front

Live-front transformers are specified as radial units and thus do not come with any fuse protection. See Figure 2.2.29.

The primary compartment is on the left, and the secondary compartment is on the right, with a rigid barrier separating them. The secondary door must be opened before the primary door can be opened.

Stress-cone-terminated primary cables rise vertically and connect to the terminals on the end of the high-voltage bushings. Secondary cables rise vertically and are terminated on spades connected to the secondary bushings.

Units with a secondary of 208Y/120 V are available up to 1000 kVA. Units with a secondary of 480Y/277 V are available up to 2500 kVA. Although not detailed in a national standard, there are many similar types available.

A loop-style live front (Figure 2.2.30) can be constructed by adding fuses mounted below the primary bushings. Two primary cables are then both connected to the bottom of the fuse. The loop is then made at the terminal of the high-voltage bushing, external to the transformer but within its primary compartment.

Dead Front

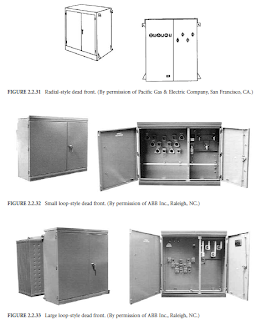

Both radial- and loop-feed dead-front pad-mounted transformers are detailed in the standard. Radialstyle units have three primary bushings arranged horizontally, as seen in Figure 2.2.31. Loop-style units have six primary bushings arranged in a V pattern, as seen in Figure 2.2.32 and Figure 2.2.33.

In both, the primary compartment is on the left, and the secondary compartment is on the right, with a rigid barrier between them. The secondary door must be opened before the primary door can be opened.

The primary cables are terminated with separable insulated high-voltage connectors, commonly referred to as 200-A elbows, specified in IEEE Standard 386. These plug onto the primary bushings, which can be either bushing wells with an insert, or they can be integral bushings.

Bushing wells with inserts are preferred, as they allow both the insert and elbow to be easily replaced. Units with a secondary of 208Y/ 120 V are available up to 1000 kVA. Units with a secondary of 480Y/277 V are available up to 2500 kVA.

Example Of Three Phase Pad Mounted Transformers

Three-Phase Pad-Mounted Transformers

Three-phase pad-mounted transformers are typically applied to serve commercial and industrial threephase loads from underground distribution systems. Traditionally, there have been two national standards that detailed requirements for pad-mounted transformers — one for live front (ANSI C57.12.22) and one for dead front (IEEE C57.12.26). The two standards have now been combined into one for all pad mounts, designated IEEE C57.12.34.

Live Front

Live-front transformers are specified as radial units and thus do not come with any fuse protection. See Figure 2.2.29.

The primary compartment is on the left, and the secondary compartment is on the right, with a rigid barrier separating them. The secondary door must be opened before the primary door can be opened.

Stress-cone-terminated primary cables rise vertically and connect to the terminals on the end of the high-voltage bushings. Secondary cables rise vertically and are terminated on spades connected to the secondary bushings.

Units with a secondary of 208Y/120 V are available up to 1000 kVA. Units with a secondary of 480Y/277 V are available up to 2500 kVA. Although not detailed in a national standard, there are many similar types available.

A loop-style live front (Figure 2.2.30) can be constructed by adding fuses mounted below the primary bushings. Two primary cables are then both connected to the bottom of the fuse. The loop is then made at the terminal of the high-voltage bushing, external to the transformer but within its primary compartment.

Dead Front

Both radial- and loop-feed dead-front pad-mounted transformers are detailed in the standard. Radialstyle units have three primary bushings arranged horizontally, as seen in Figure 2.2.31. Loop-style units have six primary bushings arranged in a V pattern, as seen in Figure 2.2.32 and Figure 2.2.33.

In both, the primary compartment is on the left, and the secondary compartment is on the right, with a rigid barrier between them. The secondary door must be opened before the primary door can be opened.

The primary cables are terminated with separable insulated high-voltage connectors, commonly referred to as 200-A elbows, specified in IEEE Standard 386. These plug onto the primary bushings, which can be either bushing wells with an insert, or they can be integral bushings.

Bushing wells with inserts are preferred, as they allow both the insert and elbow to be easily replaced. Units with a secondary of 208Y/ 120 V are available up to 1000 kVA. Units with a secondary of 480Y/277 V are available up to 2500 kVA.

PAD MOUNTED TRANSFORMERS SINGLE PHASE BASIC AND TUTORIALS

SINGLE PHASE PAD MOUNTED TRANSFORMERS BASIC INFORMATION

What Are Single Phase Pad Mounted Transformers?

Single-phase pad-mounted transformers are usually applied to serve residential subdivisions. Most single phase transformers are manufactured as clamshell, dead-front, loop-type with an internal 200-A primary bus designed to allow the primary to loop through and continue on to feed the next transformer.

These are detailed in the IEEE Standard C57.12.25 (ANSI, 1990). The standard assumes that the residential subdivision is served by a one-wire primary extension. It details two terminal arrangements for loopfeed systems: Type 1 (Figure 2.2.26) and Type 2 (Figure 2.2.27).

Both have two primary bushings and three secondary bushings. The primary is always on the left facing the transformer bushings with the cabinet hood open, and the secondary is on the right. There is no barrier or division between the primary and secondary.

In the Type 1 units, both primary and secondary cables rise directly up from the pad. In Type 2 units, the primary rises from the right and crosses the secondary cables that rise from the left. Type 2 units can be shorter than the Type 1 units, since the crossed cable configuration gives enough free cable length to operate the elbow without requiring the bushing to be placed as high.

Although not detailed in the national standard, there are units built with four and with six primary bushings. The four-bushing unit is used for single-phase lines, with the transformers connected phase-to-phase. The six-primary-bushing units are used to supply single-phase loads from three-phase taps.

Terminating all of the phases in the transformer allows all of the phases to be sectionalized at the same location. The internal single-phase transformer can be connected either phase-to-phase or phase-to-ground.

The six-bushing units also allow the construction of duplex pad-mounted units that can be used to supply small three-phase loads along with the normal single-phase residential load. In those cases, the service voltage is four-wire, three-phase, 120/240 V.

Cabinets for single-phase transformers are typically built in the clamshell configuration with one large door that swings up. Older units were manufactured with two doors, similar to the three-phase cabinets.

New installations are almost universally dead front; however, live-front units are still purchased for replacements. These units are also built with clamshell cabinets but have an internal box shaped insulating barrier constructed around the primary connections.

What Are Single Phase Pad Mounted Transformers?

Single-phase pad-mounted transformers are usually applied to serve residential subdivisions. Most single phase transformers are manufactured as clamshell, dead-front, loop-type with an internal 200-A primary bus designed to allow the primary to loop through and continue on to feed the next transformer.

These are detailed in the IEEE Standard C57.12.25 (ANSI, 1990). The standard assumes that the residential subdivision is served by a one-wire primary extension. It details two terminal arrangements for loopfeed systems: Type 1 (Figure 2.2.26) and Type 2 (Figure 2.2.27).

|

| Type 1 |

|

| Type 2 |

Both have two primary bushings and three secondary bushings. The primary is always on the left facing the transformer bushings with the cabinet hood open, and the secondary is on the right. There is no barrier or division between the primary and secondary.

In the Type 1 units, both primary and secondary cables rise directly up from the pad. In Type 2 units, the primary rises from the right and crosses the secondary cables that rise from the left. Type 2 units can be shorter than the Type 1 units, since the crossed cable configuration gives enough free cable length to operate the elbow without requiring the bushing to be placed as high.

Although not detailed in the national standard, there are units built with four and with six primary bushings. The four-bushing unit is used for single-phase lines, with the transformers connected phase-to-phase. The six-primary-bushing units are used to supply single-phase loads from three-phase taps.

Terminating all of the phases in the transformer allows all of the phases to be sectionalized at the same location. The internal single-phase transformer can be connected either phase-to-phase or phase-to-ground.

The six-bushing units also allow the construction of duplex pad-mounted units that can be used to supply small three-phase loads along with the normal single-phase residential load. In those cases, the service voltage is four-wire, three-phase, 120/240 V.

Cabinets for single-phase transformers are typically built in the clamshell configuration with one large door that swings up. Older units were manufactured with two doors, similar to the three-phase cabinets.

New installations are almost universally dead front; however, live-front units are still purchased for replacements. These units are also built with clamshell cabinets but have an internal box shaped insulating barrier constructed around the primary connections.

Subscribe to:

Comments (Atom)

Previous Articles

-

▼

2025

(162)

-

▼

December

(39)

- MASTERING SIMULATION IN ELECTRONIC DESIGN: A COMPR...

- UNDERSTANDING THE LIMITATIONS AND POTENTIAL OF CIR...

- MASTERING OSCILLOSCOPES AND LOGIC ANALYZERS: A COM...

- MASTERING OSCILLOSCOPES: A GUIDE FOR ELECTRICAL EN...

- UNDERSTANDING MULTIMETERS AND OSCILLOSCOPES: A COM...

- MASTERING ELECTRICAL ENGINEERING: THE ESSENTIAL TO...

- UNDERSTANDING CONSTANT CURRENT SOURCES IN ELECTRON...

- INNOVATIVE CIRCUITS: ENHANCING ELECTRONIC DESIGN W...

- OPTIMIZING PRODUCT DESIGN THROUGH MODULARIZATION A...

- ENGINEERING DESIGN: ADAPTING TO CHANGE IN A DYNAMI...

- ENSURING ROBUSTNESS IN ELECTRONIC DESIGN: A COMPRE...

- DESIGNING ROBUST ELECTRONIC SYSTEMS: NAVIGATING IN...

- UNDERSTANDING COMPONENT ERRORS IN ELECTRONIC DESIGN

- UNDERSTANDING ALTERNATING CURRENT: A DEEP DIVE INT...

- UNDERSTANDING ELECTRICITY: THE SCIENCE BEHIND CURR...

- UNDERSTANDING THEVENIN'S THEOREM: A DEEP DIVE INTO...

- UNDERSTANDING THEVENIN’S THEOREM: A KEY TOOL IN CI...

- MASTERING ELECTRICAL CIRCUITS: THE POWER OF THEVEN...

- MASTERING ELECTRICAL FUNDAMENTALS: A DEEP DIVE INT...

- UNDERSTANDING TIME CONSTANTS IN ELECTRONICS: THE K...

- UNDERSTANDING VOLTAGE DIVIDERS AND RC CIRCUITS IN ...

- UNDERSTANDING ELECTRICAL IMPEDANCE: THE FOUNDATION...

- MASTERING OHM'S LAW: THE CORNERSTONE OF ELECTRICAL...

- MASTERING THE FUNDAMENTALS: WHY BASIC PRINCIPLES A...

- MASTERING THE FUNDAMENTALS: THE LEGO APPROACH TO E...

- MASTERING ELECTRONIC CIRCUITS: THE PATH TO INTUITI...

- INTUITIVE SIGNAL ANALYSIS: MASTERING THE ART OF PR...

- UNDERSTANDING OSCILLATION IN ELECTRICAL AND MECHAN...

- UNDERSTANDING ELECTRICAL COMPONENTS: A DEEP DIVE I...

- MASTERING ESTIMATION IN ENGINEERING: A CRUCIAL SKI...

- MASTERING UNIT CONVERSIONS: A CRUCIAL SKILL FOR EV...

- UNLOCKING THE MAGIC OF ELECTRICITY: A GUIDE TO UND...

- UNDERSTANDING ELECTRICITY: THE DYNAMIC FORCE BEHIN...

- UNDERSTANDING ELECTRICITY: VOLTAGE, CURRENT, AND T...

- UNDERSTANDING ELECTRICITY: A DEEP DIVE INTO CHARGE...

- UNDERSTANDING ATOMIC STRUCTURE: CHARGE AND ELECTRO...

- UNDERSTANDING ELECTRICITY: A JOURNEY THROUGH ATOMS...

- MASTERING ENGINEERING PRINCIPLES: A GUIDE FOR STUD...

- UNLOCKING THE POWER OF ELECTRICAL ENGINEERING: A G...

-

▼

December

(39)