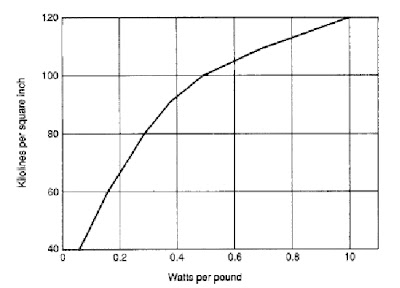

The core loss (no-load loss) of a power

transformer may be obtained from an empirical design curve of watts

per pound of core steel (Fig. below). Such curves are established by

plotting data obtained from transformers of similar construction.

The basic loss level is determined by

the grade of core steel used and is further influenced by the number

and type of joints employed in construction of the core. Figure 10-1

applies for 9-mil-thick M 3-grade steel in a single-phase core with

45” mitered joints.

Loss for the same grade of steel in a

3-phase core would usually be 5% to 10% higher. Exciting current for

a power transformer may be established from a similar empirical curve

of exciting volt-amperes per pound of core steel.

The steel grade and core construction

are the same as for Fig. 10-1. The exciting current characteristic is

influenced primarily by the number, type, and quality of the core

joints, and only secondarily by the grade of steel.

Because of the more complex joints in

the 3-phase core, the exciting volt-amperes will be approximately 50%

higher than for the single-phase core. The exciting current of a

transformer contains many harmonic components because of the greatly

varying permeability of the steel.

For most purposes, it is satisfactory

to neglect the harmonics and assume a sinusoidal exciting current of

the same effective value. This current may be regarded as composed of

a core-loss component in phase with the induced voltage (90DEG ahead

of the flux) and a magnetizing component in phase with the flux.

Sometimes it is necessary to consider

the harmonics of exciting current to avoid inductive interference

with communication circuits. The harmonic content of the exciting

current increases as the peak flux density is increased.

Performance can be predicted by

comparison with test data from previous designs using similar core

steel and similar construction. The largest harmonic component of the

exciting current is the third.

Higher-order harmonics are

progressively smaller. For balanced 3-phase transformer banks, the

third harmonic components